Food For Thought

In the simplest terms the UAEs $3.7bn food waste problem is blamed on low cost, supersized portions at restaurants and over-zealous home chefs. But the problems begin much further back in the supply chain. Logistics New ME investigates how and where improvements can be made

The UAE has a $3.7bn food waste problem but it isnt caused by people buying, cooking and serving too much food. In fact professionals from the logistics and food industry last month claimed at least 5% of the problem could be eliminated if logistics solutions were improved.

The figures are arresting: 3.27 million tonnes of food is wasted every year in the UAE, at a cost of $3.7bn, according to research conducted by Abu Dhabis Massar Solutions. The firm also estimated that a truck load of food is worth on average Dh100,000, meaning that the annual cost of food waste in the UAE is a staggering AED13.6 billion. The World Resources Institute reports that in Dubai nearly 38% of food is wasted every day, increasing to 55% during Ramadan. In Abu Dhabi, 39% of the 1.1 million tonnes of municipal waste generated in the emirate each year is leftover food discarded by residents, according to statistics released last year by the municipality.

At Gulfood Manufacturing last month in Dubai, special focus was placed on the logistics of food distribution and consumption with the launch of the Food Logistics Forum, supported by NAFL. The event is the regions only F&B logistics platform to explore critical issues shaping the future profitability and sustainability of the entire food value chain.

Food-specific logistics remains a core component of the UAE logistics industry and the issue of waste is vital for Dubai, which currently re-exports nearly half of its imported food product to other GCC countries as well as Russia, India, Pakistan and East Africa, according to the Dubai Multi Commodities Centre.

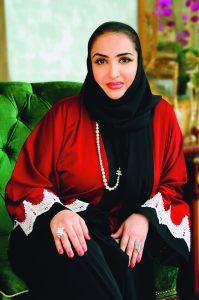

Further to recent discussions at Gulfood Manufacturing, NAFL president Nadia Abdul Aziz, is leading a campaign to strengthen the example Dubai and the UAE can set to the rest of the world. Abdul Aziz spoke on how the emirate plans to keep ahead of competing global markets and what it means for transport and logistics stakeholders at the Food Logistics Forum.

Speaking about the wider issue, Trixie LohMirmand, SVP for events and exhibitions at DWTC, said: The UNs Food and Agriculture Association has clearly stated that substantial savings can be made in food loss and waste through improved storage and transportation. These are now crucial issues as countries and industries move to reduce their carbon footprints and deliver on sustainability goals.

Brent Melvin, general manager of Supply Chain Solutions, says: The figures speak for themselves, and highlight the need for the industry to look at responsibly reducing food waste throughout the supply chain process. Although some element of waste cannot be prevented, reducing its scale will deliver significant economic, social and environmental benefits.

Making a change

Making a change

Globally, food waste is perceived as a social injustice and the solution, the simple act of individual shops and restaurants giving away their unsold produce to those in need.In the media, much has been made of the people who eat nothing but the food thrown away by supermarkets.

But what consumers and industry professionals need to understand is that the end of the supply chain is by far the least porous part. Melvin explains: F&B fleet operators play a critical role here, just as much as production and distribution companies. We have some of the best transport infrastructure in the UAE however, there is an urgent need to increase the level of efficiency of F&B fleets and logistics operations. This can be achieved by adopting innovative solutions and technologies that can help ensure the quality of food is maintained right up to final delivery. Around 5% of the food loss can be reduced through intelligent logistics, which includes real-time checks and proper driver training.

Innovation will also play a role with transport manufacturers racing to create bespoke solutions for the F&B industry.

A partnership between Gargash and Mercedes-Benz is set to roll out a new range of futuristic trucks, highlighting their fuel-efficiency and productivity, specifically for F&B distribution segments.

The promotion will also see a focus on new Mercedes-Benz electronic trucks including the Urban eTruck, the companys first fully electric truck, and its Vision van-of-the-future concept.

Telematics also plays a part, with an estimated 30% of all vehicles requiring installation of a telematics system. Last year, Massar Solutions acquired 20 Gorica designed Krone Reefer Body Semi Trailers in a move to modernise its growing supply chain business. The 15-metre long semi-trailers feature a telematic system that allows Massar and its customers to gain deeper insight and visibility into fleet operations, tracking the efficiency of shipments, as well as the condition of the shipments contents.

Collected data includes engine and driver performance, trailer temperature and payload condition, door openings, tyre pressure, travel time, and route progress. In case of irregularities, fluctuations or unexpected events, an immediate alert is sent directly to the users PC via SMS, e-mail, or a popup window.

Melvin explains: Real-time information is the real deal in managing F&B fleets efficiently. Data on temperature deviations during transit can only be retrieved at the end of a transport leg, by which time the cargo may have been subjected to temperature fluctuations resulting in wastage. Telematics can alert management and drivers immediately when the temperature in the trailer is too low or too high so that they can address the issue there and then.

The Mercedes-Benz Actros Fleet was employed by German food firm Böhmer, which purchased 42 trucks to transport its potatoes via its subsidiary Böhmer Transport.

MD Frank Zimmermann, recalls: Suddenly, not only did we have a presence of our own on the road, with vehicles sporting the Böhmer design; we also had much better access to the entire process chain, which has also had a sustainably positive impact on economy. All trucks most of them with a GigaSpace drivers cabin feature the complete, top range of equipment available.

In the UK, Pilgrim Foodservice uses a combination of 13.5- and 16-tonne Mercedes-Benz Atego chassis vehicles assigned to intensive, multi-drop delivery duties. Pilgrim supplies some 6,500 frozen, chilled and ambient food lines, as well as cleaning and disposable products, to an expanding portfolio of customers.

The 6.6m and 7.6m bodies feature twin compartments for frozen and chilled/ambient product and powerful, quiet-running Thermo King T-1000R and T-1200R multi-temperature refrigeration systems.

Enhancing operational flexibility, the bodies have movable bulkheads incorporating internal doors. The design also includes additional features specified to minimise temperature creep between compartments and restrict any loss of cooling arising from frequent openings of one or more of the triple rear doors, which have Planarctic strip curtains.

Pilgrims latest vehicles are equipped with Thermo King technology that allows operations staff to monitor vehicle temperatures remotely in real time and where necessary intervene to adjust the fridge output from a computer back at base.

MD Peter Bateman says: Its all about ease of operation and maintaining temperature integrity. We can see when the doors are opened and for how long, and if necessary make finely-tuned adjustments to the cooling system from the office.

He adds: This equipment is manufactured to a very high standard and we know it will last long enough to give us a double life. The suppliers of the vehicles also understand the crucial importance of maximising uptime. If ever we have an issue that cannot be resolved at base which doesnt happen very often they will take the vehicle back into their factory, work on it overnight and get it back to us within a matter of hours.

In practice

In practice

Implementing a combination of best practices which has driven results in other countries, one company in Dubai is aiming to tackle the local problem of reducing food waste one delivery at a time.

4Corners is a food distribution firm working with retail and hospitality clients to deliver the items and brands they need, on time. It has pioneered the Green Supply Chain concept to regulate and monitor its carbon footprint and overall efficiency. The distributor moved to a new facility in 2014 and created a bespoke centre designed specifically to meet the needs of a sustainable food supply chain.

Commercial director, Mike Walden, explains: We had undertaken a six month study on the green supply chain with the Emirates Academy of Hospitality Management, and we applied all of the relevant findings into the structure and operation of the new facility. This takes into account so many aspects of the supply chain and there is nothing else like it in the UAE at the moment from a green perspective.

The facility boasts mobile racking, so there is only ever one aisle in the warehouse; motion sensor lighting to prevent careless use; recycled plastic pallets instead of wood; Ec-H20 water cleaning system that uses 70% less water; Euro 4 standard vehicles that produce reduced emissions; electric heating mats in the freezers to prevent ice build up and reduce energy use; electric forklifts producing zero harmful emissions (vs diesel); and an electronic barcoding system and goods delivery system, removing all unnecessary paper from the supply chain.

Walden adds: Our business model can remove 90% of the carbon footprint of the majority of food businesses (or non-food in fact) across the UAE. It is a one stop shop, one order, one delivery, all products; as we operate our supply chain with all multi-temperature vehicles.

Our new facility fully supports the green initiative from our state-of-the-art warehouse managmenet systems driving customers electronic ordering right through to night time deliveries; our customers can even see live stock of their products on their phones 24/7. What needs to happen next is the operators who can affect the environment should do something about it. How many times have you seen 30 or 40 lorries queueing up to deliver products to a hotel that could arrive on one vehicle?

While the changes made to in-house operations by one company have created significant gains, it is worth taking a wider look at the food import and distribution sector as a whole. Too many suppliers not only means competitive pricing but inefficient delivery also. Certain products are sold cheaper by certain distributors, forcing chefs and retailers to purchase from multiple suppliers. Specialist suppliers also add to the loading bay traffic.

Over the pond, US-based Penske Logistics, urges retailers and distributors to work together to create an agile supply chain and avoid a situation where shops buy more than they might sell.

Within the food and beverage industry, especially within the cold chain, time-sensitive deliveries, lean supply chains and product lifecycles demand that companies can adapt quickly to changes as they arise. With a greater focus on fresh items, the market is asking for more cold chain flexibility, says Bob Daymon, vice president of transportation management operations for Penske Logistics.

Other tips from the firm include monitoring temperatures to increase shelf life and an integrated approach to business management, to ensure the entire company is working together rather than in silos.

Food waste is a costly issue for those involved in the food and beverage industry, and minimising waste can improve profits while also benefiting the environment. While there are a number of ways to reduce food waste, the National Institute of Health suggests that food manufacturers and retailers turn to the supply chain for food waste solutions, Daymon adds.

The changes required to reduce the UAEs food waste problem demand investment and a new way of thinking. They will transform business but not before businessses must transform themselves.

According to the calculations by Massar Solutions, the 3.27 million tonnes of food that is wasted in the UAE annually is equivalent to 136,250 trucks and while this cannot be completely eliminated, Melvin is keen to stress that even reducing its scale will deliver significant economic, social and environmental benefits. Massar owns almost 10,000 vehicles and manages nearly 7,000 more, belonging to customers across the UAE.

The focus, as Melvin has explained previously, should be placed just as firmly on driver education as the equipment itself and not just in operating the moving vehicle. Drivers and warehouse operators must also be educated in food storage. For example, small refrigerated vans which contain biscuits and chocolates are often switched off during the night and re-started in the morning for distribution rounds, causing temperature fluctuations and fat bloom in products like chocolate and cheese.

Without a strong sense of purpose and a cross industry approach to standards, reducing the UAEs food waste problem, even by 5%, will prove challenging. It requires a complete overhaul of current practices, investment in equipment and training of staff three points which business can be reluctant to spend on. However, if the industry can self-regulate, allowing cost efficiencies in greener transportation to trickle down to the client, perhaps the countrys food manufacturers can be convinced to go green after all.